Utilising SafeLane's marine surveys for equipment salvage

SafeLane's proprietary marine survey services can be used for more than UXO detection - it has a wide variety of applications, such as locating and salvaging equipment.

Utilising SafeLane’s marine surveys for equipment salvage

SafeLane Global’s proprietary marine survey services aren’t always utilised for the detection of unexploded ordnance (UXO).

Because our survey methodology is so accurate, it can be used to find and identify something as small as a Coke can (i.e., 300 ml cubic volume) in up to 20 meters of sub-surface from 2 meters to 100 meters of water.

So, when the owners of a quarry lost a water pump and fuel bowser due to flash flooding, and a diver was unable to locate either, our marine team got the call.

As Marine services director Ryan Prophet explained, the owners of the quarry in Ford, nr Reading in Berkshire had to find the submerged 4 tonne water pump and fuel bowser - because the former was leased, and the latter could have presented an environmental risk.

The salvage problem explained

Two years ago, our client’s quarry had been flooded when a local river burst its bank for the first time in decades – it completely flooded the area with no warning, meaning the quarry owners had no time to pre-emptively act. They did their best to protect valuable equipment, moving plant off site as the area flooded, but the equipment that couldn’t be immediately driven away was lost.

Two years of sleepless nights and angst plagued our clients until they decided to commission a diver to enter the quarry to locate the pump and bowser.

Unfortunately, water conditions meant the diver was unsuccessful. Visibility in the quarry was quite literally zero.

After further consideration and research, the client eventually Googled marine survey services and called SafeLane.

How SafeLane’s marine survey services support salvage operations

The quarry’s owners hoped SafeLane’s marine survey services could be utilised to support their equipment salvage requirements by locating the missing items.

Initially, Business Development Manager Carl Davenport attended the site to assess the conditions and the challenges, and to liaise with the client to ensure we supported their ambitions and met their timelines.

After Carl reported back and worked with the wider marine team to scope works, SafeLane deployed Project Manager Charlotte Turk and a survey team to support the equipment salvage operations from beginning to end.

The survey team undertook a side-scan survey from a compactable pontoon setup. But, as was an anticipated potential issue, there was a high level of iron ore contamination in the quarry meaning the magnetometer survey methodology would have supplied poor results.

This resulted in a seamless switch by the team to high resolution surface imaging instead.

The pump and fuel bowser were found within minutes, and their locations marked.

Supporting the salvage team and going the extra mile

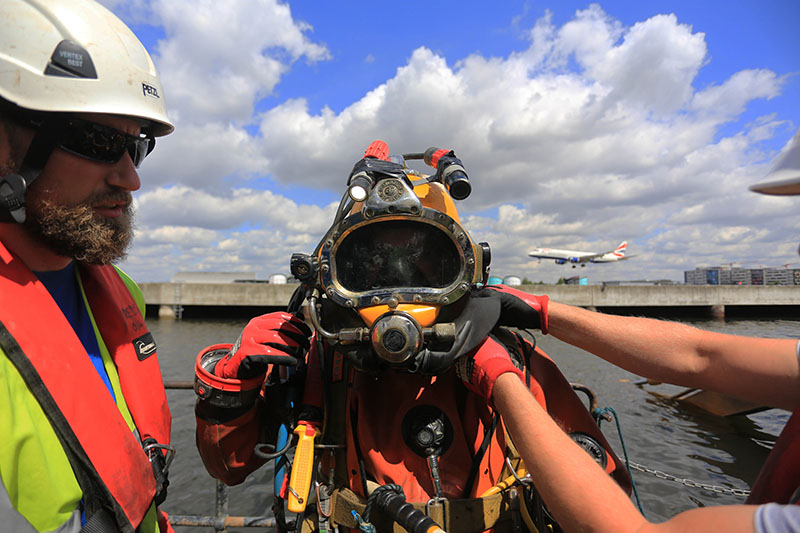

A fully authorised and well-planned salvage operation then took place. SafeLane’s Charlotte coordinated all assets, including dive personnel from RS Divers.

A combination of lift bags and plant already onsite were going to be used, before a drop in water levels rendered the lift bags useless.

Also, amazingly the bowser and pump were still connected underwater. This meant there was no leakage of fuel and the bowser’s integrity had not been affected – but it presented a unique challenge to the diver from RS Divers.

He had to enter the water, with zero visibility, and disconnect the bowser and pump without allowing fuel to leak into the quarry which would have caused an environmental disaster.

Explaining how she created a solution to overcome this conundrum, Project Manager Charlotte Turk detailed how she ensured the diver was able to determine the required disconnect manoeuvre on dry land with replica equipment.

Providing support to marine salvage operations

The diver then entered the water, alongside SafeLane personnel who had a full spill kit ready, and disconnected the bowser and pump. No more than a small cup-full of fuel was leaked before automatic shut off systems deployed, and the diver capped the pipes.

The spill kit needed in this case included a few pads (pictured) some washing up liquid and a lot of cheers from all on site - because an environmental disaster had been prevented thanks to the exceptional personnel from RS and SafeLane.

The equipment was then lifted from the water using the quarry’s own plant.

Can SafeLane’s marine survey services support your project?

SafeLane’s survey services mean we can correctly locate and identify any mass in any marine environment. Therefore, whether you’re planning to dredge and need to ensure there’s nothing dangerous that could impact your project, or you need to salvage equipment or lay a cable, trust us to deploy the correct assets and methodology to keep your project on time and budget, and your people safe.

For your next project, contact SafeLane